Recycling sewage sludge, through pyrolysis, results in high-quality biochar, containing valuable phosphorus, an essential nutrient for plant growth. Moreover, carbonization offers municipalities a safe and profitable solution in terms of the circular economy as significant renewable energy is generated and reused, while the phosphorous-rich biochar provides both agricultural benefits and sequesters carbon, when given into the soil.

However, controlled carbonization has another significant advantage: it sanitizes toxic and contaminated sewage sludge, thus protecting people and nature.

Computer-controlled process

The core of the PYREG technology is the patented reactor in combination with the downstream FLOX combustion chamber (“FLOX” stands for flameless oxidation). In the reactor, the raw material is heated largely in the absence of air at high temperatures of around 500 to 700 °C for several minutes. The computer-controlled process parameters – such as speed of conveyance of the feed material, temperature and air supply, is the key to recycling success. In the process, the phosphorus remains completely available for plants. And moreover: This treatment of sewage sludge offers great potential for the removal of many pollutants of high ecological and human health impact.

Carbonization destroys feedstock pathogens

Sewage sludge originates mainly from human excrements. Naturally, the sludge contains spores, pathogens, and pyrogens, which are of public health concern.[1] Standard hygienization of sewage sludge (e.g. heating of the sludge to 70 °C), does not eliminate all these contaminants.

The process conditions of pyrolysis (> 500 °C for more than three minutes) are much harsher even than approved sterilization conditions. Accordingly, pyrolysis eliminates all pathogens[2] and pyrogens contained in sewage sludge – including bacteria, fungi, vira, spores, parasites, antibiotic resistance genes etc. The final product, i.e. the biochar, is free of threats for public health.

Pyrolysis eliminates micropollutants from sewage sludge

Increasing concern is raised regarding the spreading of sewage sludge on farmland, due to the presence of micropollutants in sludges. Recent scientific research has demonstrated that pyrolysis will destroy or remove several types of micropollutants:

Organic pollutants (e.g. pharmaceuticals, hormone disrupting molecules):

Scientific evidence shows that at sufficiently high pyrolysis temperatures (> 500 °C) and long durations (> 3 min), all reference organic contaminants and micropollutants were completely or nearly completely degraded or driven off the solid material. A study published in 2019 by the German Ministry of Environment (Bundesumweltamt)[3] analyzed the residues of various pharmaceutical biosolids after pyrolytic treatment above 500 °C. After the process, all of the investigated pharmaceuticals were below the detection limit. The authors conclude: “With thermo-chemical treatments (i.e. pyrolysis) a complete destruction of the pharmaceutical residues is achieved. No further technical treatment measures are necessary.”

PFAS:

Per- and Polyfluoroalkyl Substances (PFAS) are eliminated by the process of pyrolysis. Kundu et al. (2021)[4] found that > 90 % of PFOS and PFOA in sewage sludge were destroyed in a pyrolysis-combustion integrated process. Evidence from the US EPA Office of Research and Development (2021)[5] carried out on the US-based company Bioforcetech’s commercially installed PYREG plant shows that pyrolysis at 600 °C for 10 minutes and combustion of pyrolysis gases at 850 °C eliminate PFAS from sewage sludge. Bioforcetech (2021)[6] has reported 38 PFAS compounds that were all kept at or removed to below detection limit in the biochar in their pyrolysis and pyrolysis gas burning process.

PAH:

Spreading sewage sludge on agricultural land is very common in Europe, although sludges potentially contain elevated levels of toxic polycyclic aromatic hydrocarbons (PAH). Properly designed pyrolysis processes can eliminate these chemical compounds, resulting in biochar with a PAH content below limit values or even detection limits: Moško et al. (2021)[7] demonstrated that slow pyrolysis at > 400 °C removes more than 99.8 % of the studied PCB, PAH, endocrine-disrupting chemicals, and hormonal compounds. The authors state: “High temperature (> 600 °C) slow pyrolysis can satisfactory remove organic pollutants from the resulting sludge-char, which could be safely applied as soil improver”.

Pyrolysis eliminates microplastic from sewage sludge

Research indicates that sewage sludge is a sink for microplastic. Thus, effective reduction of the plastic fragments is critical for potential dispersal.[8] Ni et al. (2020)[9] found that “Polyethylene and polypropylene, the two most abundant microplastics in sewage sludge, were entirely degraded when the pyrolysis temperature reached 450 °C.” Total concentrations of microplastic were reduced from 550.8 – 960.9 to 1.4 – 2.3 particles/g at pyrolysis temperatures of 500 °C. No microplastic with a particle size of 10-50 μm remained.

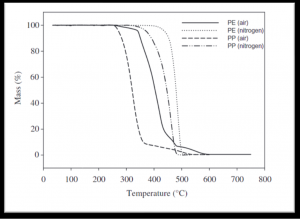

To illustrate the behavior of plastic during high temperature treatment (for example during pyrolysis), the thermal decomposition curves of PE and PP are shown in Figure 1. PE and PP thermal degradation shows a dramatic mass loss between 400 °C and 500 °C, while above 500 °C “the material degraded completely without leaving any noticeable residue.”[10] PET, a highly relevant plastic type regarding sewage sludge, starts to decompose at a temperature above 450 °C and transitions to the gas phase. PET decomposition is terminated in less than one minute (α = 1) at temperatures above 500 °C[11]. The cracked gases are of high calorific value and can be used for energy production. Thus, the pyrolysis of sewage sludge is a good method to drastically reduce microplastic in the environment.

Figure 1: TG scans of PE and PP measured at a constant heating rate in two different test environments: inert atmosphere and in air.[12]

Sources:

[1] Huygens, D., Garcia-Gutierrez, P., Orveillon, G., Schillaci, C., Delre, A., Orgiazzi, A., Wojda, P., Tonini, D., Egle, L., Jones, A., Pistocchi, A. and Lugato, E., Screening risk assessment of organic pollutants and environmental impacts from sewage sludge management, EUR 31238 EN, Publications Office of the European Union, Luxembourg, 2022, ISBN 978-92-76-57322-7 (online), doi:10.2760/541579 (online), JRC129690.

[2] Paz-Ferreiro, Jorge, Aurora Nieto, Ana Méndez, Matthew Peter James Askeland, and Gabriel Gascó. 2018. “Biochar from Biosolids Pyrolysis: A Review” International Journal of Environmental Research and Public Health 15, no. 5: 956. https://doi.org/10.3390/ijerph15050956

[3] Bundesumweltamt (2019) Arzneimittelrückstände in Rezyklaten der Phosphorrückgewinnung aus Klärschlämmen, Umweltforschungsplan des Bundesministeriums für Umwelt, Naturschutz und nukleare Sicherheit, Forschungskennzahl 3715 33 401 0, UBA-FB 002724 (https://www.umweltbundesamt.de/sites/default/files/medien/1410/publikationen/2019-03-29_texte_31-2019_arzneimittelrueckstaende-klaerschlamm_v2.pdf)

[4] Kundu, S., Patel, S., Halder, P., Patel, T., Marybali, M. H., Pramanik, B. K., Praz-Ferreiro, J., Figueiredo, C. C., Bergmann, D., Surapaneni, A., Megharaj, M., Shah, K., Removal of PFASs from biosolids using a semi-pilot scale pyrolysis reactor and the application of biosolids derived biochar for the removal of PFASs from contaminated water, Environ. Sci.: Water Res. Technol., 2021, 7, 638–649

[5] Gullet, B., EPA PFAS innovative treatment team (PITT) findings on PFAS destruction technologies, EPA Tools & Resources Webinar February 17, 2021

[6] https://ccag.ca.gov/wp-content/uploads/2020/02/BFT_FEB_2020-1.pdf

[7] Moško J, Pohořelý M, Cajthaml T, Jeremiáš M, Robles-Aguilar AA, Skoblia S, Beňo Z, Innemanová P, Linhartová L, Michalíková K, Meers E. Effect of pyrolysis temperature on removal of organic pollutants present in anaerobically stabilized sewage sludge. Chemosphere. 2021 Feb;265:129082. doi: 10.1016/j.chemosphere.2020.129082. Epub 2020 Nov 23. PMID: 33309446

[8] Charles Rolsky, Varun Kelkar, Erin Driver, Rolf U. Halden, Municipal sewage sludge as a source of microplastics in the environment, Current Opinion in Environmental Science & Health, Volume 14, 2020, Pages 16-22, ISSN 2468-5844, https://doi.org/10.1016/j.coesh.2019.12.001.

[9] Ni, B., Zhu, Z., Li, W., Yan, X., Wei, W., Xu, Q., Xia, Z., Dai, X., & Sun, J. (2020). Microplastics Mitigation in Sewage Sludge through Pyrolysis: The Role of Pyrolysis Temperature. Environmental Science and Technology Letters, 7, 961-967.

[10] Sudip Ray, Ralph P. Cooney, chapter 9 – Thermal degradation of polymer and polymer composites, Myer Kutz, Handbook of environmental degradation of materials (third edition), william Andrew publishing, 2018, pp. 185-206, https://doi.org/10.1016/B978-0-323-52472-8.00009-5

[11] Osman, A.I., Farrell, C., Al-Muhtaseb, A.H. et al. Pyrolysis kinetic modelling of abundant plastic waste (PET) and in-situ emission monitoring. Environ Sci Eur 32, 112 (2020). https://doi.org/10.1186/s12302-020-00390-x https://www.researchgate.net/figure/Reaction-progress-a-versus-the-temperature-for-the-PET-pyrolysis-where-the-coloured-and_fig1_343994995.

[12] Sudip Ray, Ralph P. Cooney, chapter 9 – Thermal degradation of polymer and polymer composites, Myer Kutz, Handbook of environmental degradation of materials (third edition), william Andrew publishing, 2018, pp. 185-206, https://doi.org/10.1016/B978-0-323-52472-8.00009-5

0 Comments