Recycling sewage sludge, through the process of pyrolysis, results in the production of high-quality biochar, containing valuable phosphorus, an essential nutrient for plant growth. Moreover, this process offers municipalities a safe and profitable solution, in terms of the circular economy, as significant renewable energy is generated and reused, while the phosphorous-rich biochar provides both agricultural benefits and sequesters carbon (thereby reducing CO2 emissions), when placed into the soil (CO2 removal certificates).

Since 2015, PYREG has been installing its proven, sustainable and scalable biochar production plants at Waste Water Treatment Plants (WWTP) throughout Germany, Denmark, Czech Republic, Sweden, as well in the United States. PYREG’s modular Systems have a small / compact footprint, which allows for integration with existing WWTP equipment such as sludge digesters, drying equipment, etc.

A significant revenue opportunity

Furthermore, the recovery of phosphorus in the wastewater treatment process ensures independence from costly mineral phosphorus imports that pollute the environment and the climate. Hence, what may seem like an additional financial burden for local authorities, is in reality, a significant revenue opportunity, as the carbonization recycling process not only produces P-fertilizer biochar, but also provides regenerative energy and enables valuable CO2 removal certificates. Hence, WWTPs can benefit from three revenue streams, whilst eliminating significant costs, such as sewage sludge transportation.

PYREG plants are now in operation at more than 50 locations around the world. And they also serve national environmental authorities, such as the US Environmental Protection Agency (EPA), as study and reference plants; an example is the PYREG plant operated at the Silicon Valley Clean Water (SVCW) WWTP, near San Francisco, California.

Biomass cycles

The heating of biomass in a low oxygen environment is called pyrolytic carbonization. In this process, organic carbon compounds are converted into a process gas and solid elemental carbon. While organic carbon compounds are degradable and natural decomposition releases greenhouse gases such as CO2 or methane (CH4) into the atmosphere, elemental carbon is stable for thousands of years. As long as this carbon is not burned, it does not react with any element and remains in its stable form as C. Thus, it can be considered a permanent carbon sink, when it is used as a soil amendment in arable farming.

The characteristics of the carbonization process

– A temperature and a process duration, high and long enough, respectively, to remove important impurities of the starting material such as viruses or micropollutants to “decompose” or “volatilize”

– The retention of important nutrients such as phosphorus in the solid phase.

– The ability to retain most of the carbon contained in the feedstock into stable carbon in the resulting biochar, thus providing a stable carbon sink. This process is referred Biochar Carbon Removal (BCR)

Autothermal carbonization

The PYREG process enables the conversion of organic residues to biochar with simultaneous recovery of thermal energy. The core of our technology is the PYREG reactor in combination with the downstream FLOX combustion chamber (“FLOX” stands for flameless oxidation). In the reactor, the raw material is heated largely in the absence of air at high temperatures of around 500 to 700 °C for several minutes. The computer-controlled process parameters – such as speed of conveyance of the feed material, temperature and air supply, is the key to recycling success. The sewage sludge is almost completely pyrolytically carbonized in a controlled process. In the process, the phosphorus remains completely available for plants.

The volatile components are freed from entrained particles by hot gas filtration and burned flamelessly as hot process gas in the combustion chamber. The resulting combustion heat is partly used to heat the reactor, so that the process is thermally self-sufficient after the start-up phase. Hence, PYREG Systems do not produce residues such as pyrolytic oil, which are costly and problematic to dispose of.

The FLOX combustion, with flue gas recirculation, in conjunction with hot gas filtration, allows very low flue gas emissions – especially low amounts of nitrogen oxides and dust – while simultaneously creating biochar and usable waste heat. Thus, PYREG Systems represent a NetZero technology, as they require significantly less energy to operate than the renewable energy they produce themselves.

Valuable output

The resulting excess heat is used for preparatory drying of the raw material or fed into heating networks. Alternatively, it can be used to generate electricity should that be a goal. The resulting biochar can be used as a high-quality fertilizer. This is possible because the carbonization process at more than 500 °C sanitizes and decontaminates the dried sludge. And: The phosphate recovery rate with this process is more than 98 %.

High fertilizing effect

The commitment to resource conservation requires us to recover phosphorus from sewage sludge to make it available to farmers. Of the methods for phosphorus recovery, carbonization at temperatures of 500 to 700 °C is among the most carbon efficient and results in a product that can used directly as a fertilizer for soil applications without further chemical extraction. In 2021, the Hessian State Laboratory (LHL) in Giessen, commissioned by the Hessian Ministry of the Environment conducted a trial to compare the plant availability of ten recycled phosphates with that of triple superphosphate (TSP) and with that of sewage sludge. The recyclates differed in terms of their production, composition and product form.

TSP is a calcium dihydrogen phosphate-containing fertilizer, which has a converted content of more than 46 diphosphorus pentoxide (P2O5). The phosphorus availability of the PYREG carbonate reached almost 90 % of the effect of the TSP (regrowth performance). This TSP fertilizer with 46% P2O5 costs currently between 700 and 800 €/t. Thus, municipalities will be able to generate revenues instead of incurring significant costs.

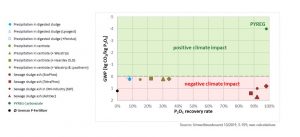

Climate protection benefits

Compared to conventional fertilizer, sewage sludge carbonates have a negative global warming potential. A study by the German Federal Environment Agency from 2019 comes to the conclusion that conventional fertilizer production in Germany emits about +1.2 kg CO2-equivalents per kg of P2O5 [1]. Phosphate recovery processes such as precipitation in digested sludge or centrate or sewage sludge ash cause CO2 emissions. Compared to the greenhouse gas potential of these processes PYREG carbonates from sewage sludge have a negative global warming potential of -4.01 kg CO2 equivalents per kg P2O5. Consequently, the recovery of phosphate in the Pyreg process and the final application of the biochar contributes to the fight against global warming and to advance our goal of net zero.

In addition, the phosphate – recovery rate of the sewage sludge carbonates is more than 98%, which is within the range of other thermal treatments and is far better than that of precipitation processes with a recovery rate of less than 40 %.

No microplastics

Still the direct application of sewage sludge onto arable land is still a preferred method in some European countries. Researchers showed that sewage sludge contains significant amounts of microplastics. The elimination of microplastic contamination can only be achieved by high temperatures during treatment and a sufficiently long retention time. Ni et al. 2020 [2] stated that “polyethylene and polypropylene, the two most common microplastics in sewage sludge, are completely degraded at a carbonization temperature of 450 °C.”

No pathogens

Sewage sludge mainly consists of human excreta and naturally contains pathogens which by their very nature, are a significant risk to public health. The process conditions of pyreg carbonization of more than 500 °C for more than ten minutes are more extreme than those of the CDC (Centers for Disease Control and Prevention) of the U.S. Department of Health and Human Services.

According to the Steam Sterilization Disinfection and sterilization guidelines of the CDC, the minimum sterilization conditions are as follows 132 °C for four minutes or 250 °C to remove pathogens such as bacterial endotoxins under dry conditions (dry heat sterilization).

No contaminants

In a study published by the Federal Environmental Agency in 2019 pharmaceutical residues of various biosolids were analysed after pyrolytic treatments at over 500 °C[3]. After carbonization, all the parameters of the of the analysed pharmaceuticals were below the detection limit. The authors concluded that thermochemical treatments such as carbonization achieve complete destruction of the drug residues.

No PFASs

Another example: perfluorinated and polyfluorinated alkyl substances (PFAS) are very persistent, long-lived and accumulate in the environment and in our bodies. For this reason they are often referred to as “Forever Chemicals”. In this regard, a study by the US EPA from the year 2021 shows that the integrated carbonization and combustion process of the PYREG plant operated near San Francisco successfully eliminates PFASs [4].

Conclusion

The CO2-emitting incineration of sewage sludge or the untreated application to soils is no longer justifiable from the point of view of climate, environmental and health aspects. Instead, carbonization is a profitable process for recycling the valuable raw material(s) from sewage sludge and supplying it to agriculture as refined biochar.

For municipalities, this has several positive effects: they close material cycles, meet their decarbonization targets, generate significant amounts of renewable energy and create a high-quality, safe and environmentally friendly end product, which they can sell as an alternative to phosphorus fertilizer.

Sources:

- Umweltbundesamt, „Ökobilanzieller Vergleich der P-Rückgewinnung aus dem Abwasserstrom mit der Düngemittelproduktion aus Rohphosphaten unter Einbeziehung von Umweltfolgeschäden und deren Vermeidung“, UBA Texte 13/2019, ISSN 1862–480

- Ni et al., 2020, „Microplastics Mitigation in Sewage Sludge through Pyrolysis: The Role of Pyrolysis Temperature“, Environ. Sci. Technol. Lett. 2020, 7, 12, 961–967, https://doi.org/10.1021/acs.estlett.0c00740

- Umweltbundesamt, „Arzneimittelrückstände in Rezyklaten der Phosphorrückgewinnung aus Klärschlämmen“, UBA Texte 31/2019

- Environmental Protection Agency, „PFAS innovative treatment team (PITT) findings on PFAS destruction technologies“, February 17, 2021, https://www.epa.gov/chemical-research/pfas-innovative-treatment-team-pitt

0 Comments