YOUR NEW BUSINESS MODEL: SUSTAINABILITY

From waste to value –

Driving sustainability and a circular economy

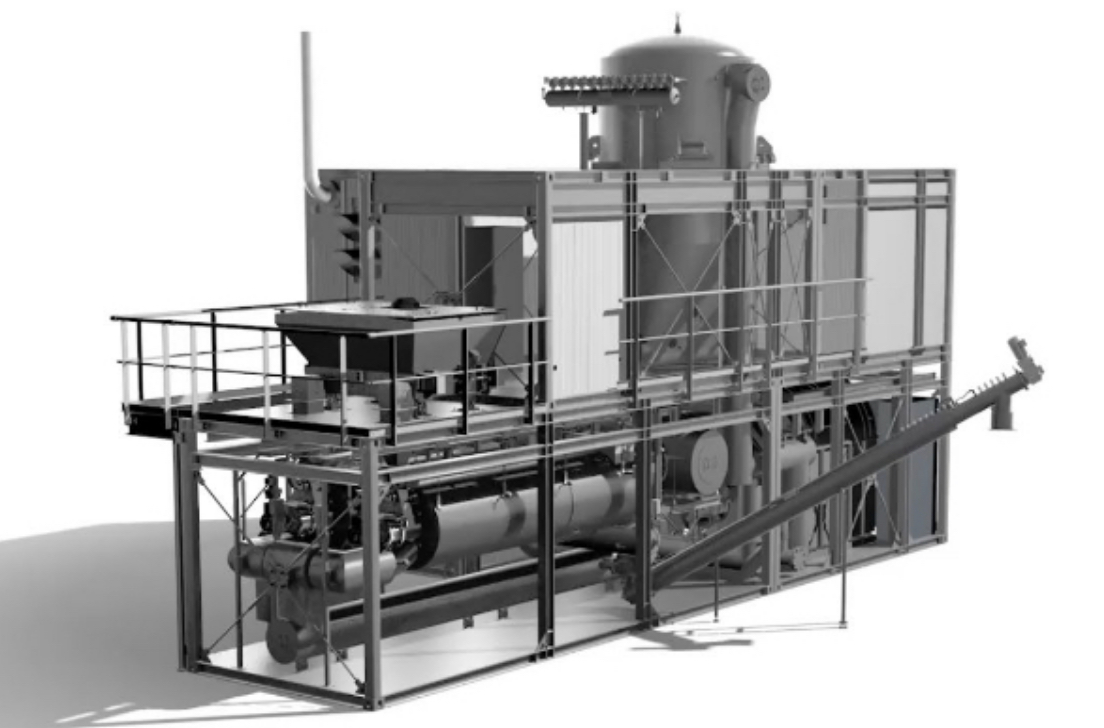

Transforming organic waste streams into Biochar and renewable energy is our business.

PYREG systems locally upcycle your organic waste into valuable Biochar, thereby “closing the loop” and demonstrating a true Circular Economy.

During the carbonization process, the majority of the carbon is actually sequestered in the resulting Biochar, thereby inhibiting the release of CO2 into the atmosphere, for centuries. Furthermore, as the PYREG system operates at temperatures of up to 750°C, organic-based pollutants (such as solvents and microplastics) are practically eliminated and mineral pollutants are filtered, to ensure they cannot re-enter the environment.

The advantages of

• waste volume reduction • a high quality product • renewable energy • CO2 sink certificates

to be used either as a yield model or to benefit the companies CSR goals.

CO2 Sink

Certificates

Waste Volume

Reduction

Extracted Re-

newable Energy

High Quality

End-Product: Biochar

Turn positive now!

Carbon removal with Pyreg can be used, either as a yield model or, to benefit the companies CSR goals.

CO2-Sink Certificates

CO2-Sink Certificates

2.100 t CO2/year

262.500 €*

(Puro Earth, 01.11.22, base price 125€)

Upcycling your waste

Upcycling your wasteto Biochar

900 t/year

= 720.000 €

CO2-Carbon Storage

CO2-Carbon Storage

2.100 t CO2/year

180.000 trees

Renewable Energy

Renewable Energy

600 kW ≙ ~ 4,8 GWh/year

240,000 €/year

+ additional savings

compared to liquid gas 1,300 t CO2

By example woodchips 80%DS, 19 MJ/kg DS

* Production-related CO2 emissions have already been deducted

Co2 Sink Certificates

Carbonization is a climate protection instrument

During this carbonization process, most of the carbon is actually sequestered in the resulting biochar, thereby inhibiting the release of CO2 into the atmosphere, for centuries. This sequestered CO2 amount can be certified and used either to achieve sustainable corporate goals (CSR) or to trade them on the open market.

Waste volume reduction

Disposal of industry waste and sludge is becoming increasingly demanding due to high environmental requirements, increasing disposal costs and capacity bottlenecks.

The carbonization process allows a final mass reduction of up to 90%, which not only reduces your waste materials but also your transportation and disposal costs, significantly.

Extracted Renewable Energy

The carbonization process is self-sustaining; after completion of the starting-up phase no further external energy is required to run the process, as the energy from the waste is sufficient for the continuance of the thermal treatment. It is even possible to benefit from the excess heat produced; an amount of 150 up to 750 kWth may be used for drying of humid biomass, for heating or power generation.

Up to 5.6 GWhth usable heat energy per year as hot water, steam or thermal oil can be used.

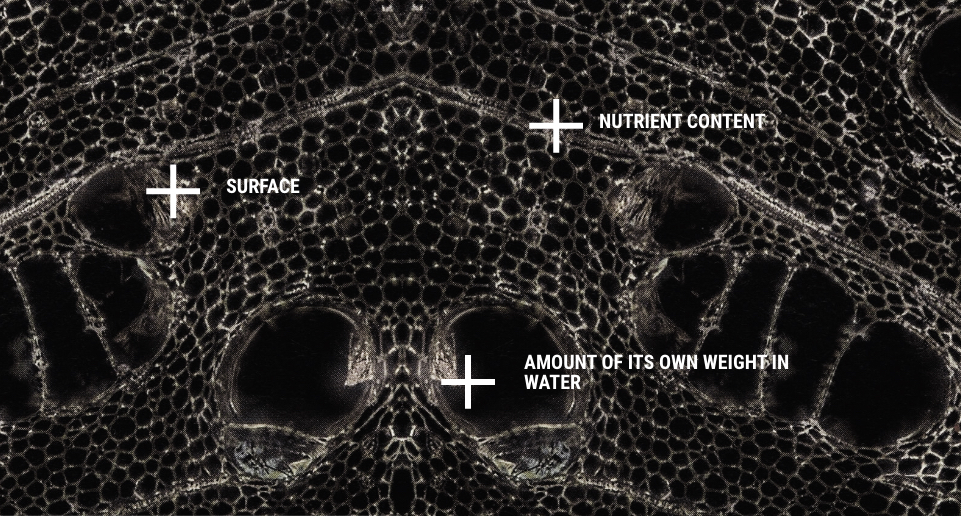

High Quality Product: Biochar

High quality biochar has a great variety of characteristics and effects; it acts like a sponge, retaining water and nutrients. These qualities enable biochar to be used in many applications, such as:

• Filtration • Soil improvement • Feed-additive

The quality and therefore the application areas depend on the input material. Low-quality biochar can be used as filling material in production or as a building material additive in asphalt or concrete.

Either way – waste can be used again in a sustainable way to close the loop, demonstrating a true Circular Economy.