Your path to Net Zero

Carbonization – a profitable Negative Emissions Technology for industrial companies (NET)

Why do we need to remove carbon (CDR)?

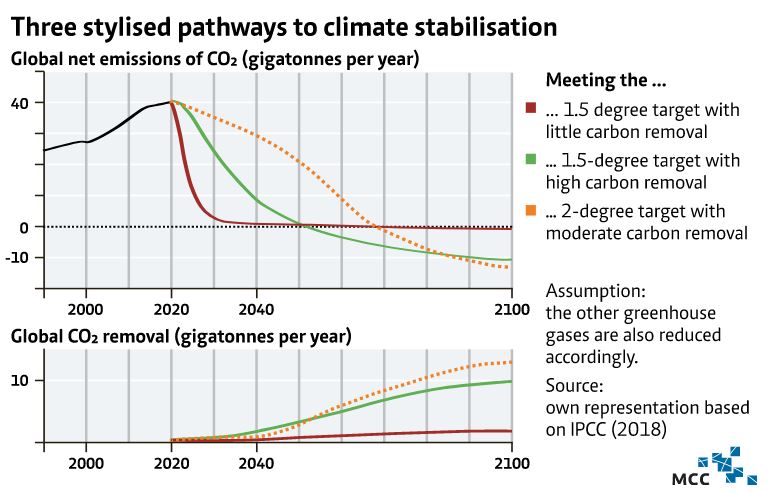

In Paris, all countries worldwide committed to keep global warming below 2 degrees Celsius. This means that the remaining carbon budget is very limited – and that we must all rapidly reduce greenhouse gas emissions. But even then, as is now apparent, mankind will not achieve the goal without relying on carbon removal.

How to keep global warming below 1.5°C or 2°C (Source: MCC)

The solution: Negative Emission Technologies (NETs)

The longer the world delays ambitous emissions reductions, the greater its carbon debt. Only negative emissions technologies can repay this debt by the year 2100. Humankind is increasing its dependence on such technologies, even though their use is associated with great uncertainties.

transforming “waste” into CO2 sequestring biochar:

a proven & profitable Negative Emission technology (NET)

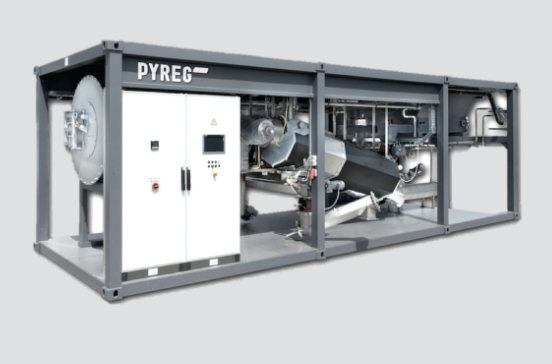

Pyreg has a solution and uses a PyCCS process to bind the carbon in biochar. Used as a soil conditioner in agriculture or as an filling additive in concrete, the CO2 ends up in a permanent carbon sink. With a PYREG system, carbonaceous residues are carbonized and up to 3 tons of CO2 per ton of biochar are permanently sequestered.

These carbon sinks, just like reforestation and humus growth, are without alternative to counteract the climate crisis. After all, emission reductions alone are not enough. To achieve the goal of the European Union, which is to become climate neutral by 2050, the annual sink volume must increase to at least 850 million tons of CO2.

Carbonization is a climate protection instrument

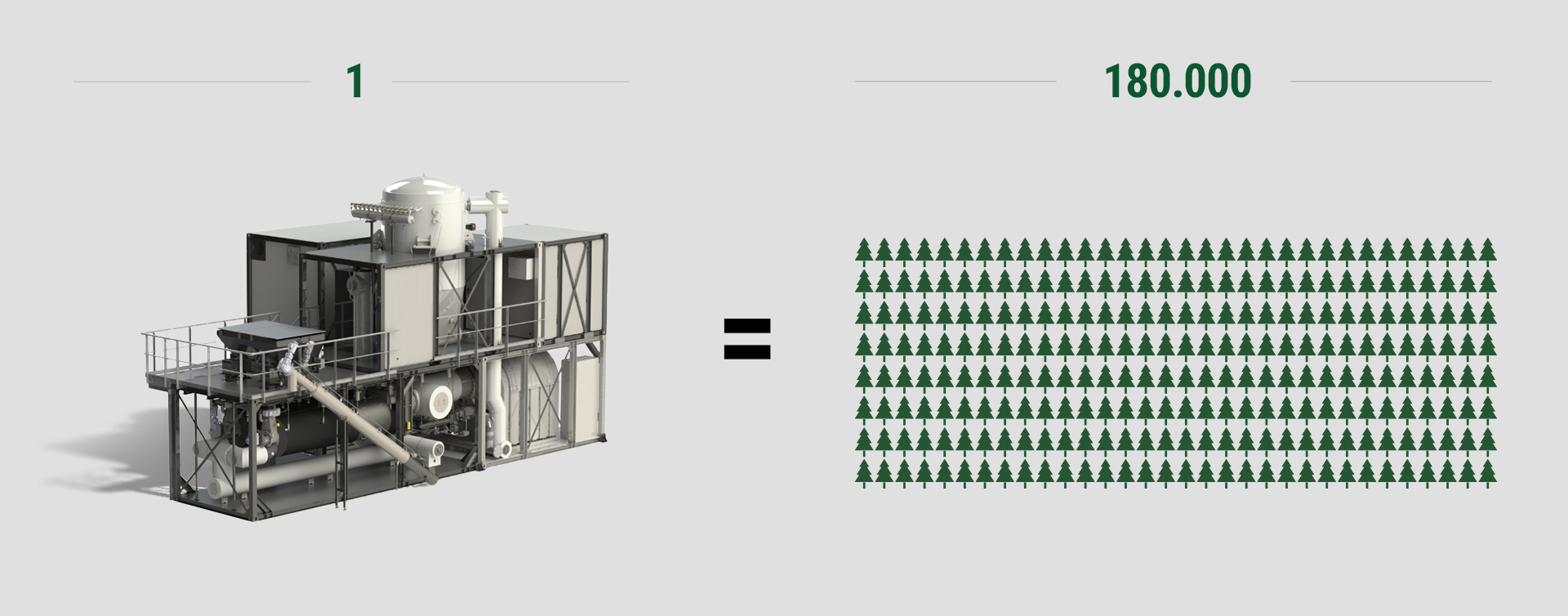

Using the PYREG Standard System PX 1500, an average output of 900 tons of Biochar can be produced every year. Incorporated into the soil as a soil improver, this can sequester as much CO2 per year as 180.000 trees. (Source: Waldzentrum Universität Münster (2019))

OPERATING 1 YEAR

EQUIVALENT TO THE YEARLY GROWTH OF 180.000 TREES

Generate your own CO2-certificates

By upcycling your residual materials into climate-protecting biochar, your production becomes climate-neutral. You can even trade additional storage capacities as CO2-certificates on the voluntary market. Our partner, Carbonfuture, is the first trading platform that meets the high EBC standards. Here, based on our type certification, some of our customers are already listed. Become part of this carbon sink industry!

YOUR GUARANTEE:

the EBC Seal

PYREG plants are EBC type-certified, a voluntary industry standard in Europe designed to ensure consistent and verifiable standards for climate-protective biochar production.

With PYREG you meet remarkable 8 of the 15 UN SDGs

The sustainability goals set by the UN are becoming increasingly important.

The PYREG technology helps companies meet these requirements today, instead of waiting for tomorrow.

Biochar increases soil properties and fertility and thus contributes to a sustainable agriculture.

Due to its enormous surface Biochar offers an excellent capacity to store nutrients and water in the soil.

PYREG carbonization generates renewable energy that can either be used on site or be fed into the local heating network.

PYREG closes the loop in carbon cycles by transforming organic waste into a valuable resource, clearing the path to "green transformation" for these industries.

Biochar can be extracted from the organic waste of cities and then serve as a water reservoir for urban green spaces that are burdened by climate change.

By recycling carbonaceous waste in a sustainable way, PYREG technology closes the loop, lowers the CO2 footprint and generates renewable energy at the same time.

Biochar is included in the IPCC special report as a promising negative emission technology (NET), mitigating climate change.

Due to its enormous surface of 200-500 m² per gram and a high porosity, Biochar retents water and nutrients dissolved in it and thus combats desertification and biodiversity loss.

Turn positive now!

Carbon removal with Pyreg can be used, either as a yield model or, to benefit the companies CSR goals.

CO2-Sink Certificates

CO2-Sink Certificates

2.100 t CO2/year

262.500 €*

(Puro Earth, 01.11.22, base price 125€)

Upcycling your waste

Upcycling your wasteto Biochar

900 t/year

= 720.000 €

CO2-Carbon Storage

CO2-Carbon Storage

2.100 t CO2/year

180.000 trees

Renewable Energy

Renewable Energy

600 kW ≙ ~ 4,8 GWh/year

240,000 €/year

+ additional savings

compared to liquid gas 1,300 t CO2

By example woodchips 80%DS, 19 MJ/kg DS

* Production-related CO2 emissions have already been deducted

Carbonization drives sustainability

and enables circularity

Better urban climate growth thanks to biochar

For more than 10 years Stockholm has been testing alternative plant substrates for the stressed city trees. Biochar was able to score with several advantages: Significantly more young plants could survive the first critical years, since the roots have more space to grow (less compaction of the soil) and are continuously supplied with water and nutrients by the biochar.

Overall, the trees’ resistance improved and they were able to survive dry periods and heavy rains more easily. This not only protects the tree population, but also improves the urban climate.

CO2 Sequestration

PYREG GmbH is a world-leading manufacturer of machines for carbonizing organic waste into high quality carbon-binding biochar. With over 50 carbonization systems sold, these systems are capable of sequestering 55,000 tons of CO2 per year while producing 20,000 tons of biochar and 125 GWh of renewable energy.

Excess Thermal Energy Is used

Pyreg allows a customer to process their excess polymer waste (e.g. green waste from vineyards or pistachio groves, wood packaging from the automotive industry) in a continuous and autothermal process, i.e. the system generates its own thermal energy from the process. The excess thermal energy can either be used as hot water, steam or electricity and hot water for on-site production, replacing fossil fuels, or it can be fed into a local or district heating network. In this way, communities can achieve heat transition under their own steam.