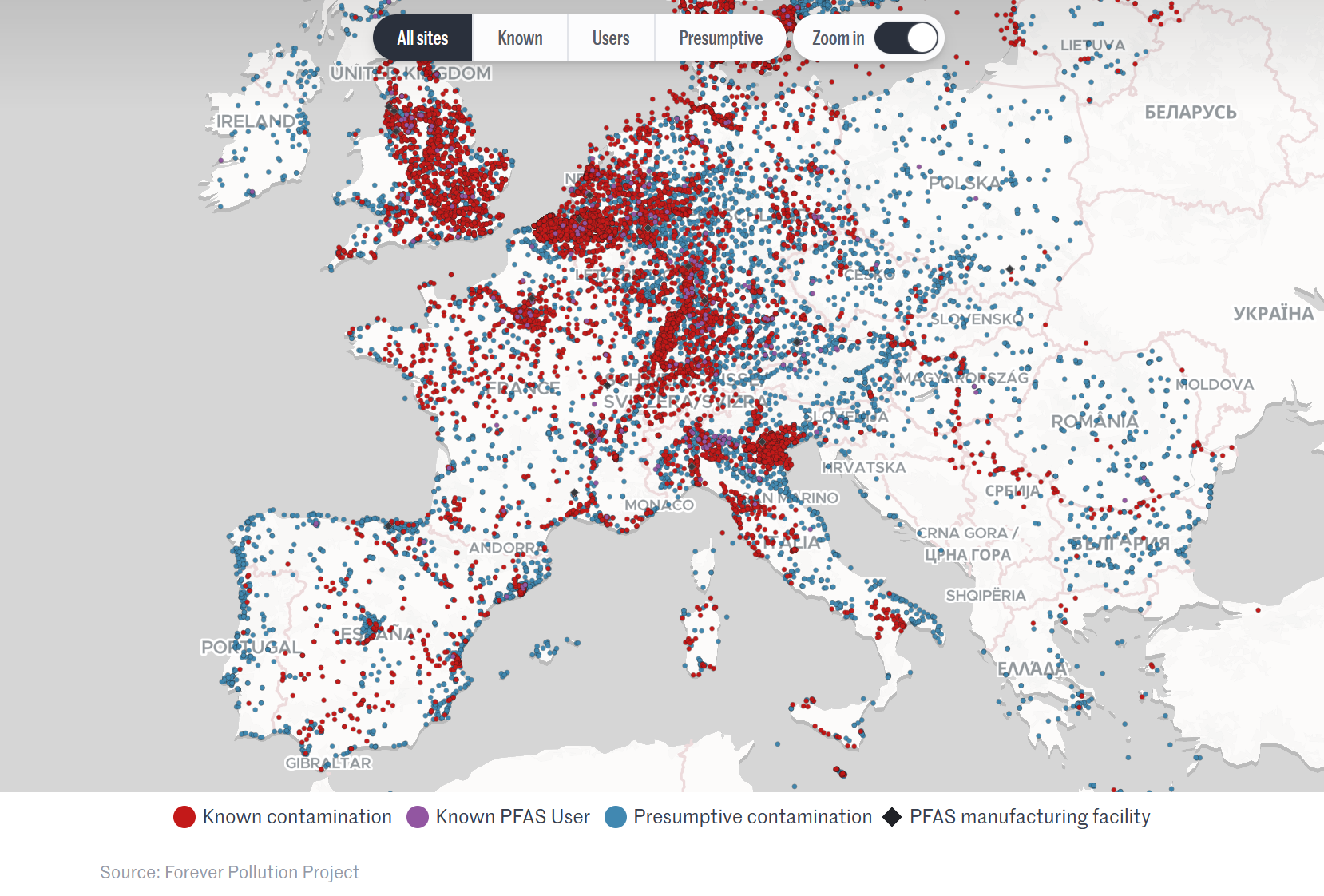

Per- and polyfluorinated alkyl substances (PFAS), also known as the Forever Chemicals, are a large chemical family of over 4,700 highly persistent chemicals that don’t occur in nature. PFAS are the most persistent synthetic chemicals to date. They hardly degrade in the natural environment and have been found in the blood and breastmilk of people and wildlife all round the world. PFAS tend to contaminate water, food chains, and soils at trace levels for generations.

Sources of PFAS contamination include paper mills, landfills, firefighting training facilities and fluorochemical plants. After decades of use, PFAS are ubiquitous in soils, groundwater and surface water. This puts pressure on wastewater treatment plants to adequately treat waste streams to prevent further spread of PFAS chemicals and increases pressure to remediate contaminated soils. This is where biochar comes into play.

Source: https://www.lemonde.fr/en/les-decodeurs/article/2023/02/23/forever-pollution-explore-the-map-of-europe-s-pfas-contamination_6016905_8.html

Source: https://www.lemonde.fr/en/les-decodeurs/article/2023/02/23/forever-pollution-explore-the-map-of-europe-s-pfas-contamination_6016905_8.html

Scientific research has demonstrated that PFAS are eliminated by the process of pyrolysis. Kundu et al. (2021) found that > 90 % of PFOS and PFOA in sewage sludge were destroyed in a pyrolysis-combustion integrated process. Evidence from the US EPA Office of Research and Development (2021) carried out on the US-based company Bioforcetech’s commercially installed PYREG pyrolysis plant shows that pyrolysis at 600 °C for 10 minutes and combustion of pyrolysis gases at 850 °C eliminate PFAS from sewage sludge. Bioforcetech (2021) has reported 38 PFAS compounds that were all kept at or removed to below detection limit in the biochar in their pyrolysis and pyrolysis gas burning process. At the Fårevejle wastewater treatment plant in Denmark, sewage sludge pyrolysis at a temperature of 650 °C and a residence time of more than 3 minutes has showed to eliminate all 7 PFAS compounds previously detected in the feedstock.

In addition to PFAS destruction Biochar made from sludges, used as a sorbent, binds already existent contaminants due to his high surface and properties. What is a sorbent ? Previous studies have postulated that high surface area, porosity, and high carbon content are important for the sorption of organic pollutants (Ahmad et al., 2014, Cornelissen et al., 2005; Hale et al., 2016; Zimmerman et al., 2004 ). Nowadays, activated carbon (AC), generally from fossil coal sources such as anthracite, is the most commonly used sorbent for soil remediation due to its high porosity and high carbon content (Hagemann et al., 2018). Biochar is an alternative to activated carbon, which can be costly and chemical and energy intensive to produce (Ahmed et al., 2019). The main advantage of biochar over AC is its greater sustainability, as demonstrated by an endpoint life cycle analysis (Sparrevik et al., 2011) due to its potential for carbon sequestration (Smith, 2016) and reduced use of chemicals (Zheng et al., 2019). Biochar is often produced from wood-based sources (Hale et al., 2016). However, from a circular economy perspective, it is at least as attractive to use lightly contaminated waste such as sewage sludge as a substrate for the production of biochar sorbents. Pyrolysis of sewage sludge to biochar is the possibility of a more sustainable waste management alternative to landfill or incineration, as it would remove many of the contaminants present in the sludge, including much of the PFAS (Sajjadi et al., 2019), and produce a sorbent for PFAS.

Sewage sludge biochars as effective PFAS-sorbents

In May 2023, there was now a groundbreaking study showing that biochar from raw and digested sewage sludge can be used as an effective sorbent for PFAS in most environmental contexts, with similar or better efficiencies than AC. This study is performed with biochar produced at Lindum AS (Drammen, Norway) by slow pyrolysis at 700 °C and a residence time of 20 minutes for WCBC and SSBC2 and 40 minutes for SSBC1 using Biogreen technology. “High porosity in the right size range and carbon content were probably the main parameters responsible for the high sorption strength observed in the sludge-derived biochars, together with some possible influence of amine functional groups.” (Krahn, Cornelissen et al. 2023).

According to Prof. Cornelissen’s research team, further studies should examine a larger range of biochar samples prepared at different pyrolysis temperatures to identify the characteristics ideal for PFAS sorption, such as surface area, pore volume, carbon content and mineral content (mainly Ca and Fe). Finally, studying the effect of activation of sludge chars on sorption strength could be useful for further improving their sorption properties.

0 Comments