In addition to production of premium biochar, PYREG plants offer the advantage of multiple uses of the heat generated in the carbonization process. Thus, our customers can use this heat for drying feedstock (e.g. sewage sludge), supplying the heat as green heat to local and district heating systems (e.g. municipalities or municipal utilities) or to generate process steam (e.g. industrial plants or manufacturing industry).

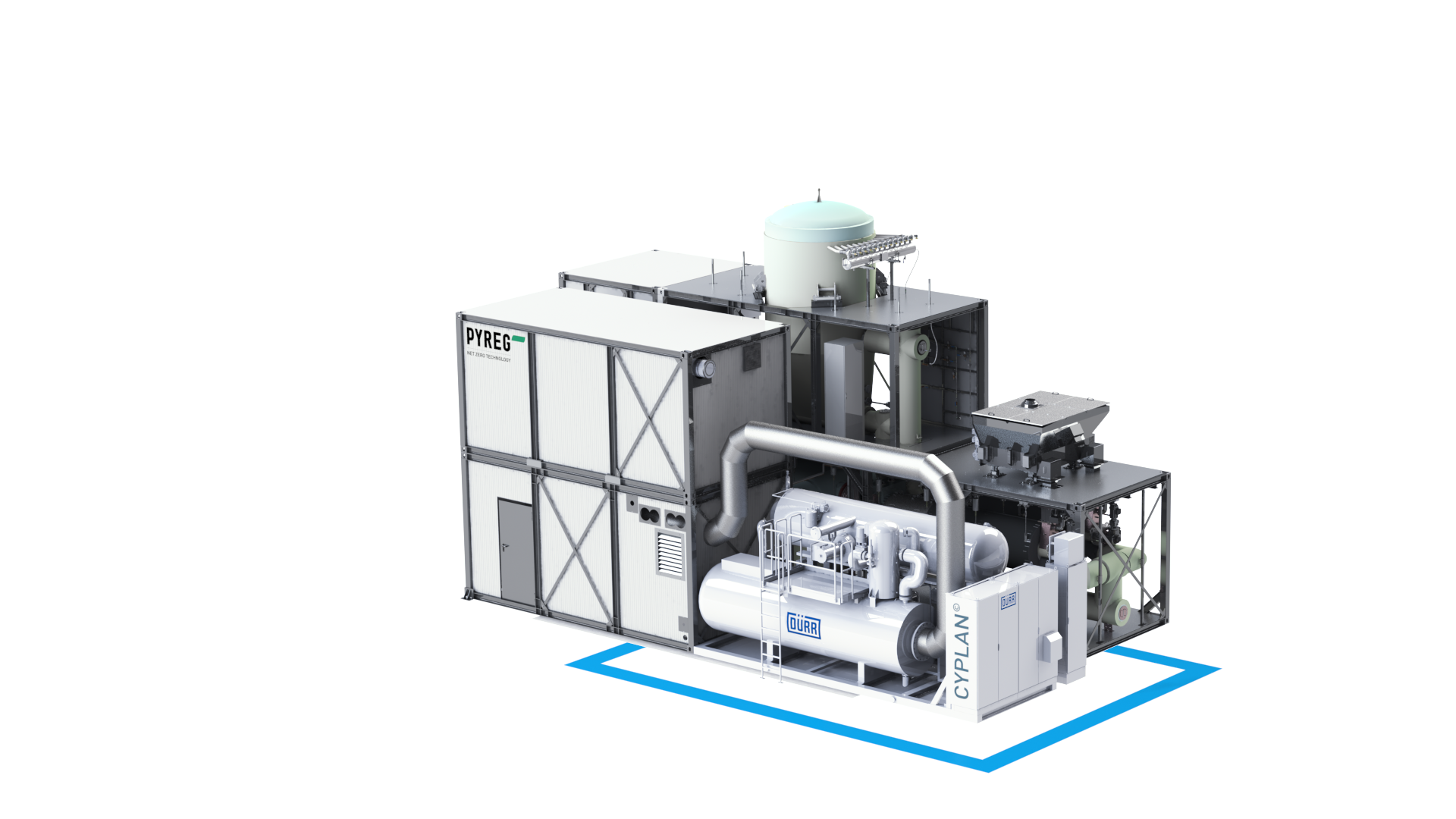

With the integration of a Cyplan® ORC module (Organic Rankine Cycle), PYREG is now going one step further: the ORC module generates electrical power from decentralized waste heat sources. The possibility of directly utilizing thermal energy in waste gases up to 500 °C is a unique selling point of Cyplan® technology by Dürr Systems AG and is thus the ideal complement to PYREG’s carbonization technology.

“By cooperating with PYREG, two German technology market leaders are demonstrating a true win-win situation, setting new standards in their markets,” says Sven Jensen, who is coordinating the cooperation as sales manager on the Dürr Systems AG side. “Especially in the small to medium power range, many ORC plants lack efficiency. Here, the fully integrated Cyplan® ORC technology is unsurpassed in terms of flexibility and electrical efficiency.”

PYREG provides largely dust-free exhaust gas due to the built-in hot gas filter in the pyrolysis process. With Dürr’s direct evaporation technology, the hot exhaust gases can be taken directly into the primary heat exchanger (evaporator) of the ORC system. An intermediate circuit, e.g. thermal oil, is not necessary, which minimizes costs and transmission losses.

Since the thermal energy is coupled into the ORC system at higher temperatures, the electrical efficiency is more than twice as high compared to an ORC solution with hot water interface, where the thermal energy is transferred to hot water and then fed to the ORC system.

In addition, the Cyplan® ORC offers the possibility of cogeneration. Here, the condensation heat from the ORC process is provided at a temperature level of up to 95 °C, while electricity is generated in parallel. This represents a valuable heat flow which can be used for pre-drying the feedstock. For biomass with lower water content, the throughput of the pyrolysis plant is thus higher. Alternatively, this low-temperature heat can be used for process purposes or for feeding into a heat network.

With the integration of the Cyplan® ORC module into the PYREG plant, the majority of the heat produced is still available to the customer for further use. The electricity produced is higher than the total plant’s energy consumption, offering attractive additional income from electricity marketing.

In total, Dürr’s high temperature ORC offers an overall efficiency of about 95% (16% electrical power (gross) plus about 79% heat) compared to about 8% electricity generation (gross) by low temperature ORC plants.

0 Comments